F4 / MULTIPHASE FLOW

The majority of flows in nature and in industry are the result of interactions between multiple phases of matter. These flow regimes are significantly more complex than single phase flows and require the detailed treatments that are only available in multiphysics simulations.

The subject of multiphase flows encompasses a vast spectrum of contexts, disciplines, and applications; it is enough to make your head spin. The wide array of numerical modeling approaches can be just as overwhelming.

The majority of processing technologies leverage multiphase flows, from cavitating pumps to industrial dryers to separation tanks to fluidized bed reactors. Likewise, nature shows a preferential bias for multiple phases, from rain and snow to biological flows.

The ability to predict the behavior of these natural and industrial processes is paramount in our efforts to control or improve them. There are three methods for obtaining knowledge used in making such predictions; (1) the experimental study of laboratory-sized models equipped with appropriate instrumentation, (2) the theoretical study of mathematical equations and models, and (3) the computational study leveraging modern computational software and hardware. The scale and complexity of most multiphase flows makes the application of the first two approaches challenging and the computational approach preferred.

Generally speaking, there are two classes of multiphase flow: dispersed flows and separated flows. In order to make accurate predictions, an engineer must be knowledgeable in both the physical nature and the numerical modeling approaches specific to each.

In dispersed flows, a secondary phase is distributed at low volume fractions within a primary, continuous phase. The canonical example is that of gaseous bubbles in a liquid. In separated flows, two or more continuous streams of different fluids are separated by interfaces where. The canonical example is a hydrological flow where there is a clearly visible boundary separating the heavier water from air.

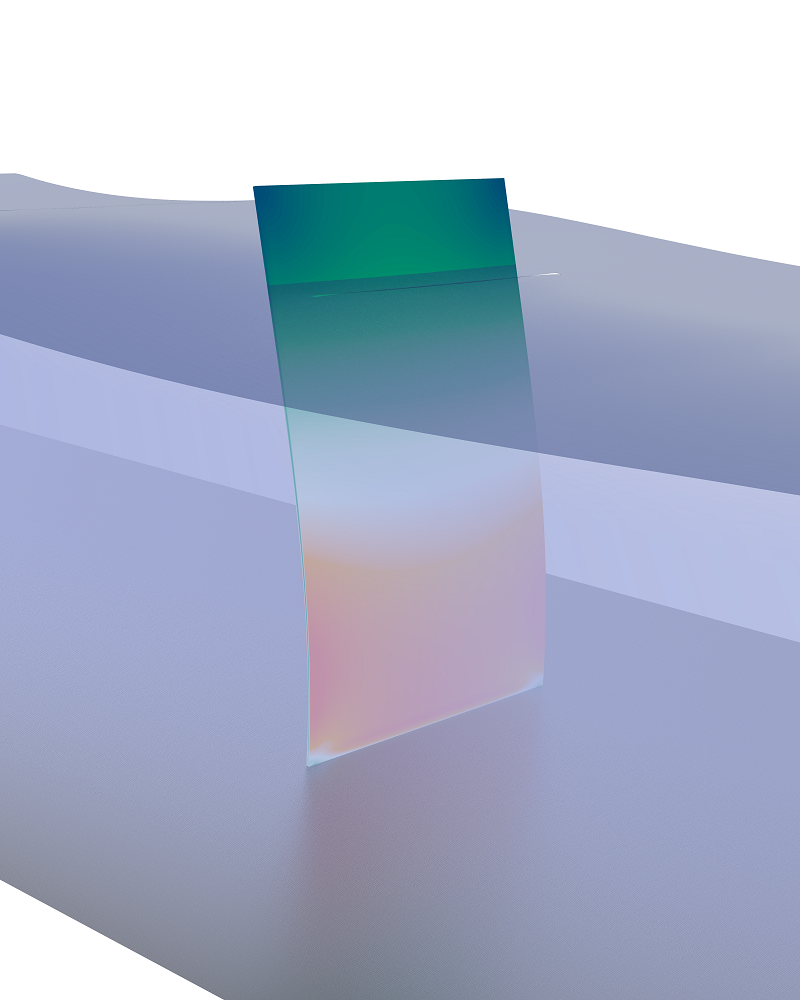

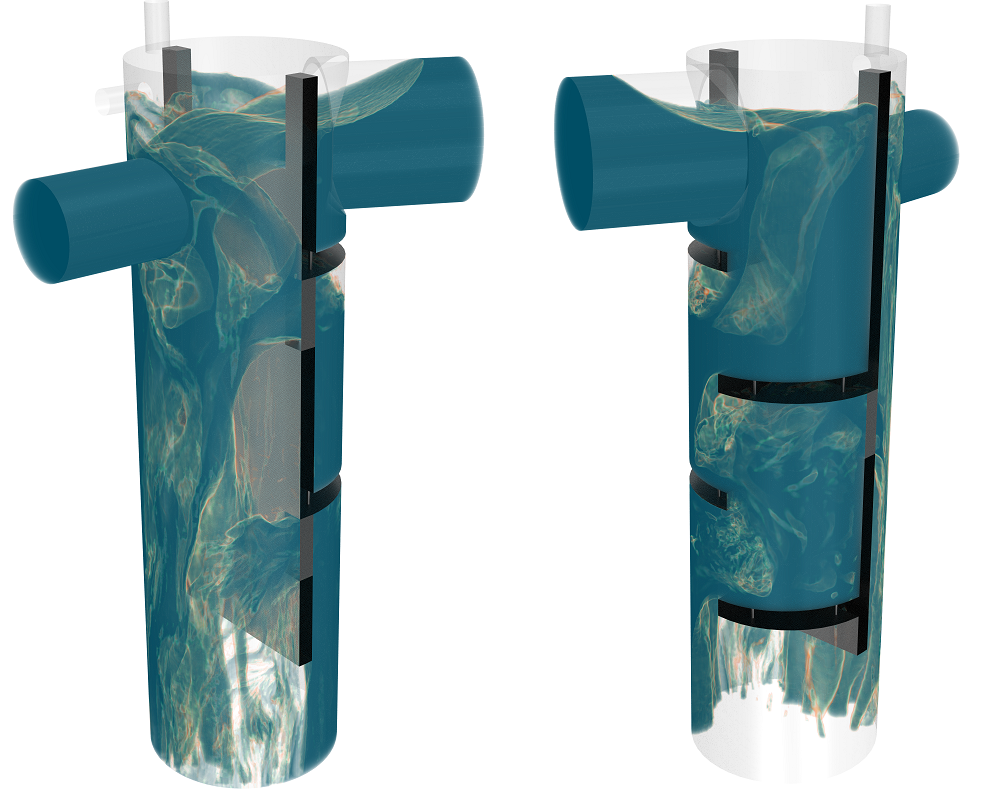

For separated flows, the recently introduced Volume of Fluid (VOF) method allows us to accurately track the motion of the interfaces between phases and model phase change effects like boiling, evaporation, condensation, cavitation, solidification and melting. This model is well suited for applications including marine hydrodynamics and seakeeping, river and dam hydraulics, stormwater runoff and drains, and wastewater treatment plants.

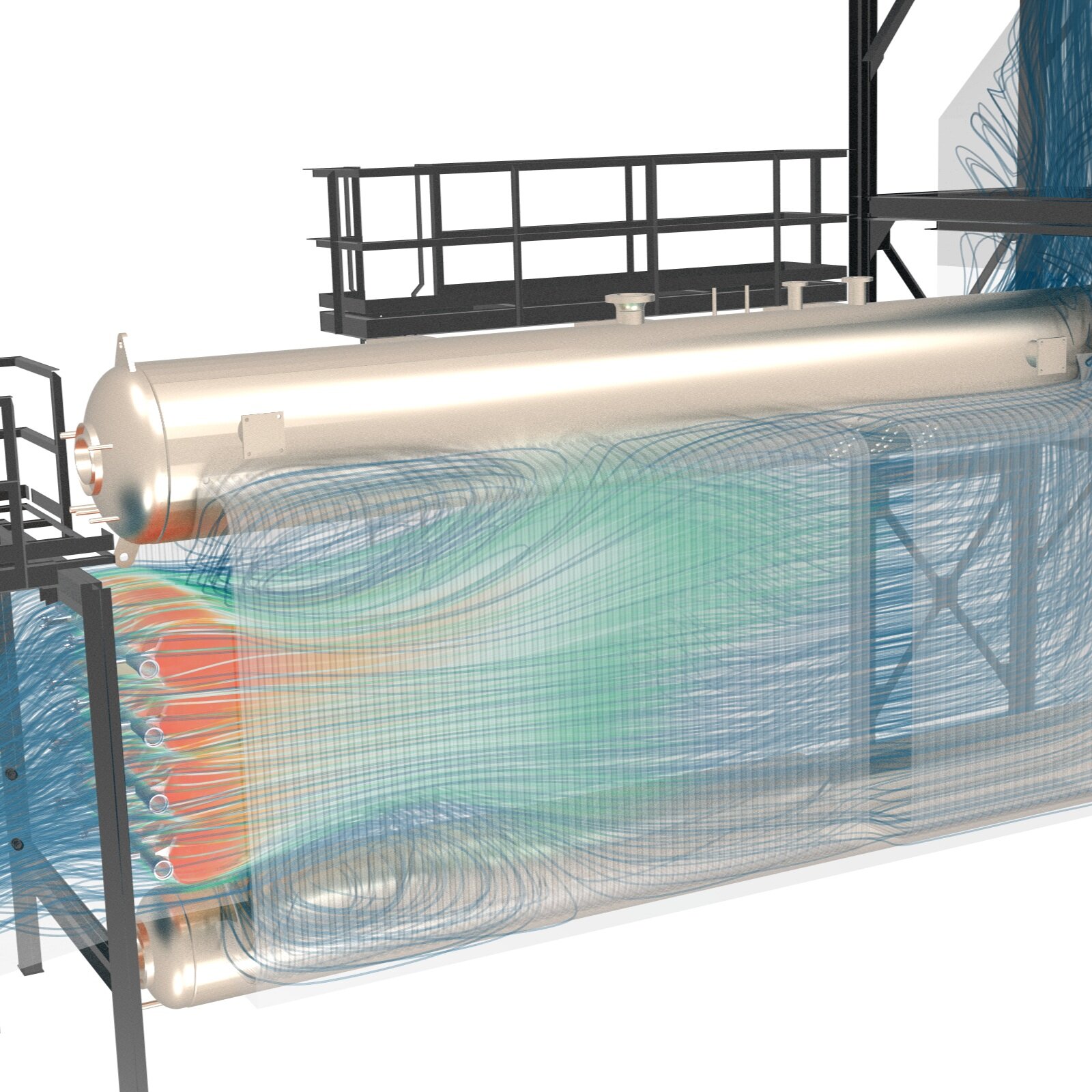

For dispersed multiphase simulations we typically lean on two core modeling approaches. The first, called the Eulerian method, comes in two flavors. The simpler of the two, the multiphase mixture model, assumes a single phase that acts as a mass weighted combination of the two phases at all locations. The second, more complicated method, models each of the phases in its full Navier-Stokes glory with phase interactions defined by slip velocity and other empirically derived relations. These Eulerian method are commonly used in modeling fluidized beds, miscible and immiscible mixtures, and bubbly flows.

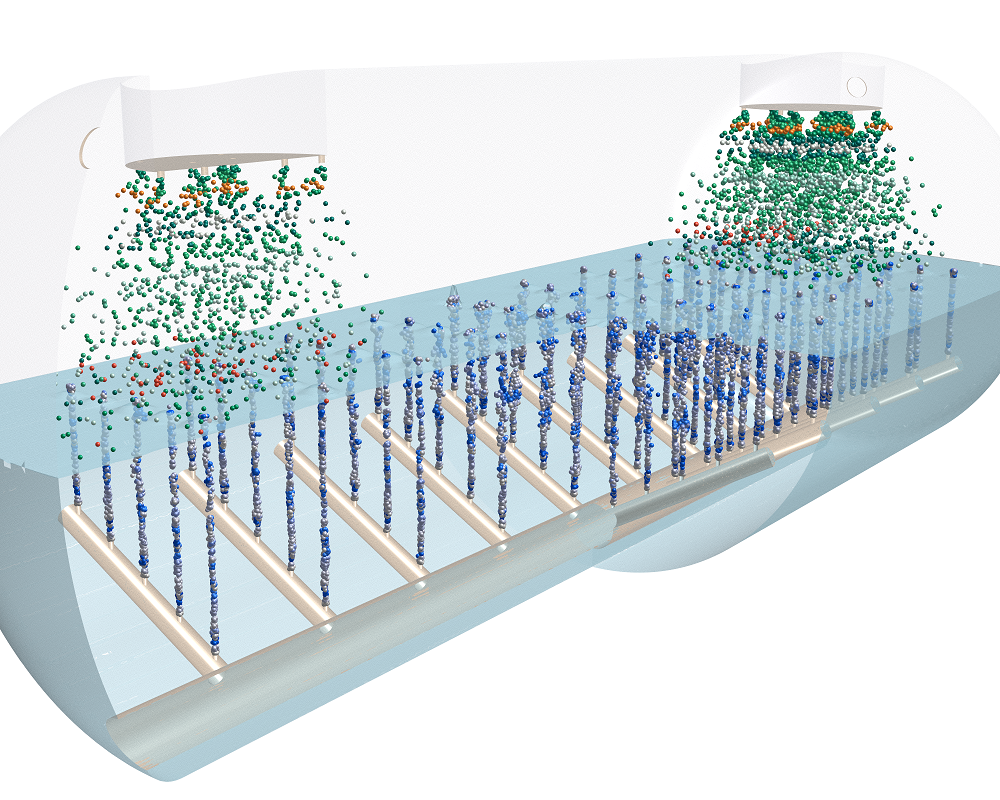

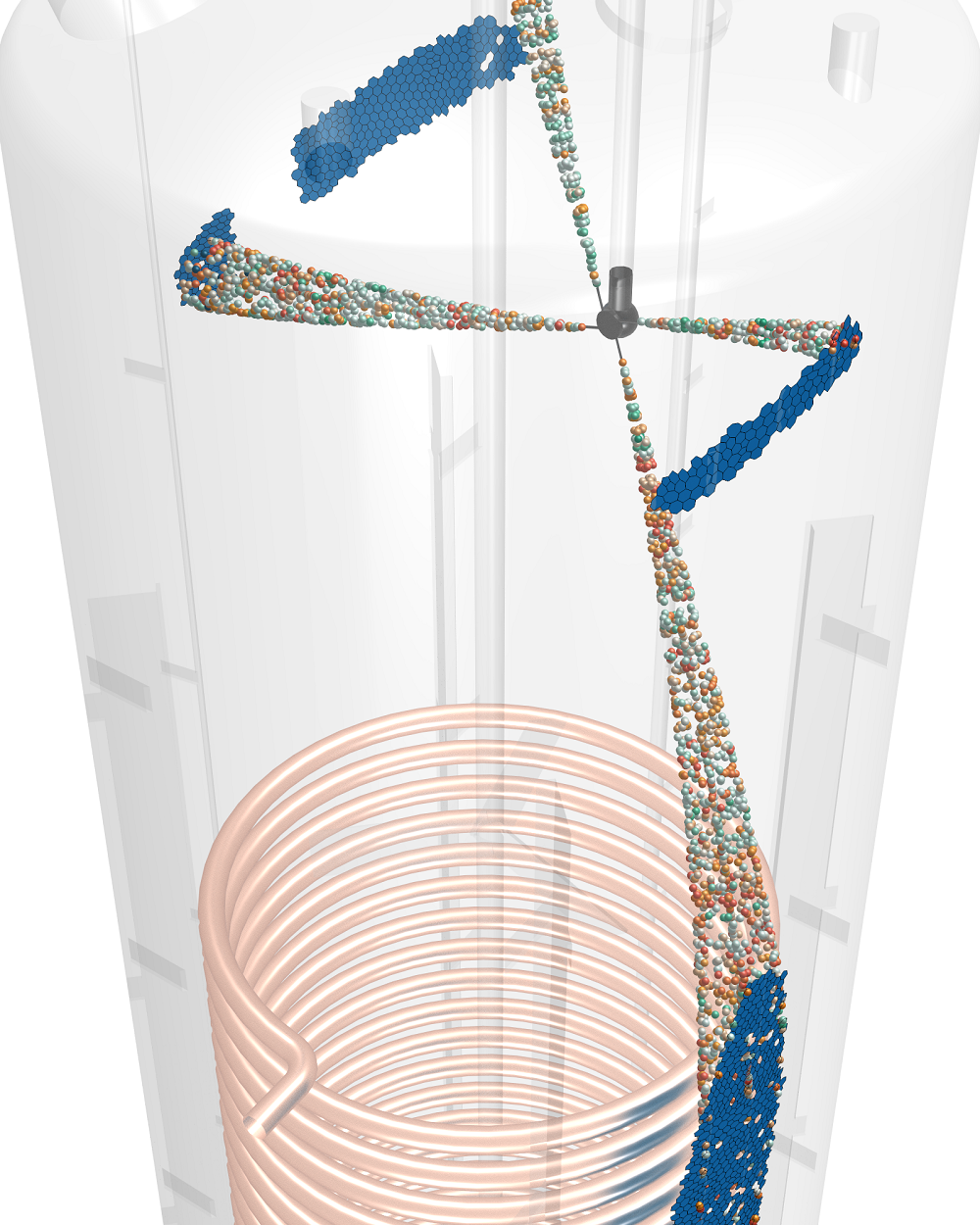

The second approach, known as the Lagrangian method, models the continuous phase according to the Navier-Stokes equations but the secondary, dispersed phase as a collection of discrete parcels, each obeying Newton’s laws of motion. Each of these phases can impact the other through any number of physical interaction mechanisms according to the user’s discretion.

All of the multiphase models discussed here can be combined in any fashion with one another and with other physics models such as chemical reactions, turbulence models, conjugate heat transfer, radiation, and electrodynamics.