F8 / DISCRETE ELEMENT MODELING

For many years our understanding of particle flow systems has been guided by empiricism. With recent gains in computing power and sophisticated computational models, it is now possible to determine the bulk behavior of granular flows without resorting to experimentation.

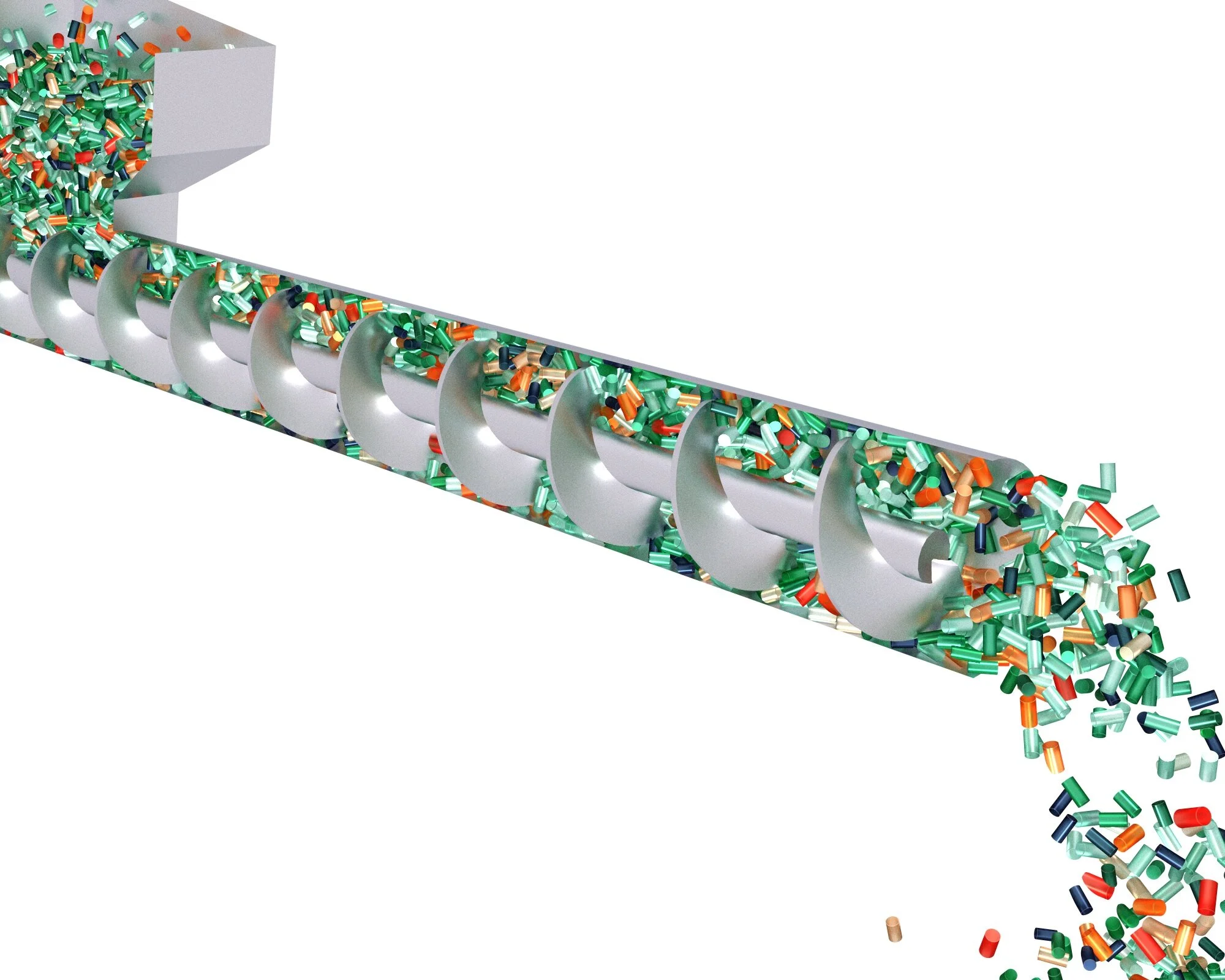

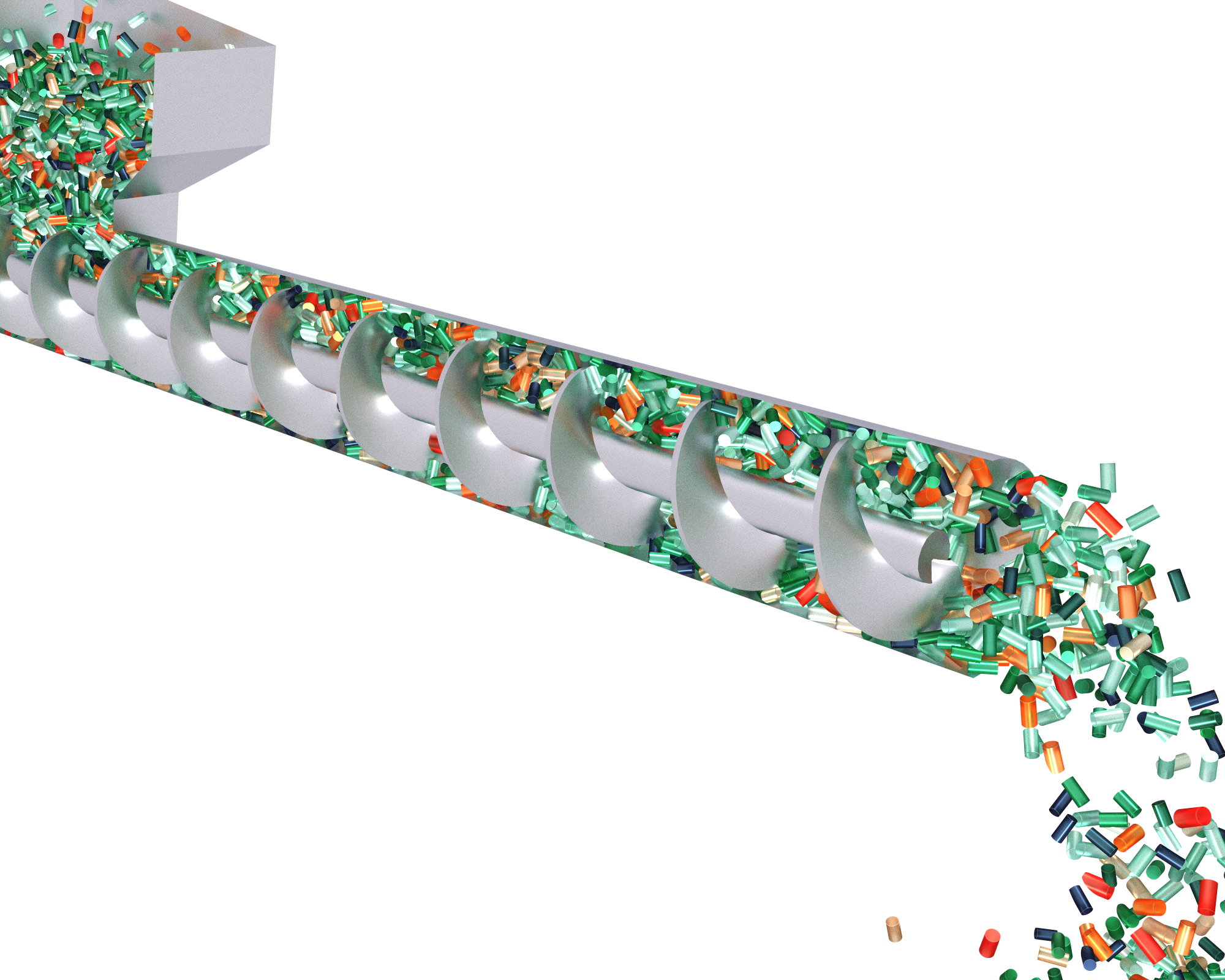

To develop or scale a process involving granular flows through experimentation is expensive and time consuming, and often doesn’t allow for optimization or for increasing understanding of “why” some designs perform well while others don’t. To overcome this challenge, scientists and engineers can now rely on state-of-the-art computational simulations using what is known as the Discrete Element Method (DEM).

DEM is a Lagrangian technique which uses interactions of arbitrary shaped particles to model material behaviors. In DEM simulations, discrete particles collide with each other and with surfaces. Using contact detection algorithms and applying suitable contact models, the DEM model calculates the forces acting on particles. Accelerations, velocities and positions are then calculated using Newton’s laws of motion and numerical integration.

Examples of equipment that benefit from an improved knowledge of the underlying science of granular flows include rotary kilns, grain silos, mixing equipment, pneumatic conveying, catalytic crackers and cyclonic separators, to name a few.

DEM is a versatile tool for modeling particulate material behavior in pharmaceutical, chemical, food, ceramic, metallurgical, mining, and other industries.

Macroscopic granular particles or flow involving fluids and granular particles are everywhere - in industry, environment and our everyday lives: sugar, sand, ores, tablets, chemicals, biomass, detergents, plastics, crops, fruits need to be harvested, produced, processed, transported and stored.

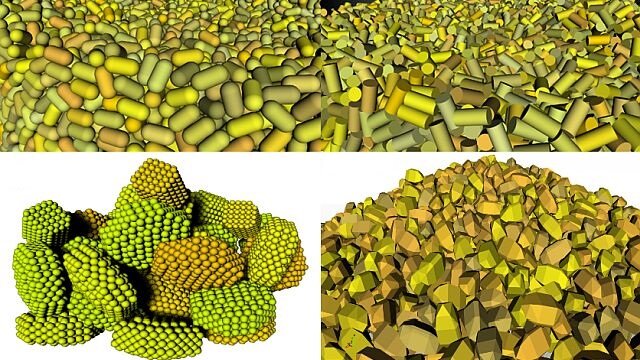

Coupled with Computational Fluid Dynamics, a CFD-DEM is a powerful tool in optimization and design of particle processes.

In particular, in the production and processing of granular matter, solids mixing plays an important role. Granular materials such as sand, polymeric particles and fertilizers are processed in equipment such as fluidized beds, rotary kilns and absorbers. Although a variety of industrial mixers are available, segregation effects may occur and result in undesirable performance. For example, mixing plays an important role in preventing hot-spots, off-spec products and undesired agglomerates.

Since solids mixing is difficult to characterize experimentally it is an ideal application for CFD-DEM multiphysics simulations.