CFD for Tunnel Ventilation

CFD Aids Tunnel Engineers in Maximizing Air Quality and Ensuring Fire Safety

Tunnels are modern marvels of engineering, providing speedy and efficient modes of transport for both people and goods. With hundreds of tunnels crisscrossing our cities and connecting different parts of the world, tunnel engineering has become increasingly complex, with the need to ensure adequate airflow and fire safety.

Understanding the Role of CFD in Tunnel Engineering

Computational Fluid Dynamics (CFD) has emerged as a powerful tool in tunnel engineering, enabling tunnel designers and engineers to simulate and analyze air movement, temperature, and concentration of pollutants. Using CFD, engineers can create virtual models of tunnels, assess the ventilation systems, and design fire suppression systems, ensuring that the tunnels are safe, energy-efficient, and eco-friendly.

CFD is a cutting-edge technology that simulates fluid flow and heat transfer in complex geometries. In the context of tunnel engineering, CFD can simulate the airflow, temperature, and concentration of pollutants, allowing engineers to evaluate the ventilation and fire safety systems. It is a highly advanced and specialized field, requiring expertise in fluid mechanics, numerical analysis, and computational methods.

Applications of CFD in Tunnel Design and Construction

CFD can be applied to various aspects of tunnel design and construction. One of the most important applications of CFD in tunnel engineering is predicting airflows and temperatures. By simulating the airflow and temperature inside the tunnel, engineers can ensure that the ventilation system is effective and efficient. This is particularly important in tunnels that are used for transportation, such as road tunnels, where the air quality can have a significant impact on the health of the passengers and the drivers.

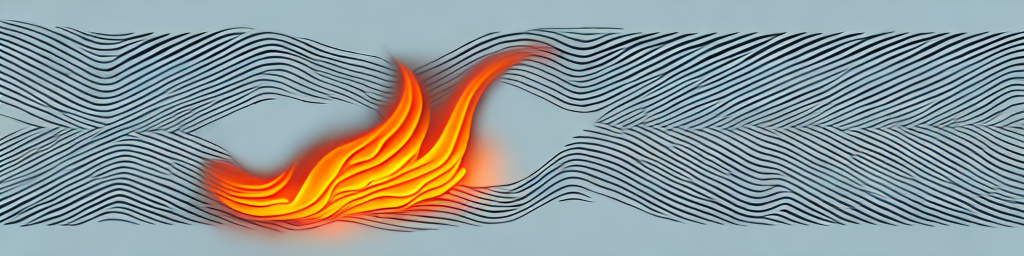

Another important application of CFD in tunnel engineering is controlling smoke movement in case of fire. By simulating the smoke movement inside the tunnel, engineers can design fire suppression systems that are effective and efficient. This is particularly important in tunnels that are used for transportation, such as road tunnels, where a fire can have catastrophic consequences.

CFD can also be used to optimize ventilation systems. By simulating the airflow inside the tunnel, engineers can identify areas where the ventilation system is not working effectively and make adjustments to improve its performance. This can lead to significant energy savings and improved air quality inside the tunnel.

The air quality in tunnels is crucial for the health and safety of passengers and workers. Poor air circulation can lead to the accumulation of pollutants such as carbon monoxide and nitrogen oxides, which can cause respiratory problems, nausea, and headaches.

Assessing Ventilation Systems and Airflow Patterns

Using CFD, engineers can simulate airflow patterns in tunnels and evaluate the effectiveness of ventilation systems. They can model different scenarios and test the impact of various design parameters such as fan speed, duct size, and diffuser layout. By optimizing the ventilation systems, engineers can improve air circulation, reduce pollutant concentrations, and enhance passenger comfort.

Reducing Pollutant Concentrations and Emissions

Pollutant emissions from vehicles are a significant source of air pollution in tunnels. CFD can be used to simulate the dispersion of pollutants and assess their concentration levels. Engineers can model the effects of different types of vehicles, fuel types, and driving speeds to optimize the ventilation systems and reduce pollutant emissions. By minimizing the concentration of pollutants, engineers can improve the air quality and reduce the health risks associated with tunnel travel.

Optimizing Energy Efficiency in Tunnel Ventilation

Tunnel ventilation systems require significant amounts of energy to operate. CFD can help engineers optimize the design of these systems to minimize energy consumption while still ensuring adequate airflow and air quality. By modeling different scenarios and testing various design parameters, engineers can identify the most energy-efficient solutions, reducing both costs and carbon emissions.

Ensuring Fire Safety through CFD Simulations

Fire safety is a critical issue in tunnel engineering, with the risk of smoke and toxic gases posing a significant threat to passengers and workers. CFD can simulate the effects of a fire and assess the performance of fire suppression systems.

Predicting Smoke Movement and Heat Transfer

Using CFD, tunnel engineers can predict the movement of smoke and heat during a fire event. They can model different fire scenarios and evaluate the effectiveness of ventilation systems in controlling smoke movement. This information can be used to develop evacuation plans and design fire suppression systems.

Evaluating Evacuation Scenarios and Emergency Response

CFD can simulate the evacuation of passengers and workers during a fire event, assessing the effectiveness of emergency response plans. Engineers can model different evacuation scenarios, taking into account factors such as crowd density, exit capacity, and visibility. By identifying potential bottlenecks and designing efficient evacuation plans, engineers can minimize the risk of casualties.

Designing Effective Fire Suppression Systems

Using CFD, engineers can evaluate and optimize the performance of fire suppression systems, such as sprinklers and water mist systems. They can simulate the behavior of water droplets and assess their effectiveness in controlling flames and reducing smoke. By designing effective fire suppression systems, engineers can minimize the spread of fire and smoke, ensuring the safety of passengers and workers.

Case Studies: Successful CFD Applications in Tunnel Engineering

CFD has been widely used in tunnel engineering, with many successful applications in different parts of the world. Here are some examples:

Gotthard Base Tunnel, Switzerland

The Gotthard Base Tunnel is the world's longest and deepest railway tunnel. CFD simulations were used to optimize the ventilation and smoke control systems, ensuring adequate air quality and fire safety. The simulations helped engineers to identify potential flow reversals and pressure fluctuations and design appropriate measures to control them.

Eurasia Tunnel, Turkey

The Eurasia Tunnel is a road tunnel connecting the European and Asian sides of Istanbul. CFD simulations were used to evaluate the ventilation systems and optimize the airflow patterns. The simulations helped engineers to design a cost-effective ventilation system that ensures air quality and energy efficiency.

Citybanan Tunnel, Sweden

The Citybanan Tunnel is a new railway tunnel in Stockholm. CFD simulations were used to optimize the ventilation and smoke control systems, ensuring passenger safety and comfort. The simulations helped engineers to design an efficient and cost-effective ventilation system that complies with stringent safety standards.

Conclusion

CFD has emerged as a vital tool in tunnel engineering, enabling engineers to optimize ventilation and fire control systems, ensuring adequate air quality and fire safety. By using CFD simulations, engineers can improve passenger comfort, reduce energy consumption, and minimize the environmental impact of tunnels. As tunnels become more complex and interconnected, the use of CFD will become increasingly important, ensuring that tunnels remain safe and reliable transport links for generations to come.