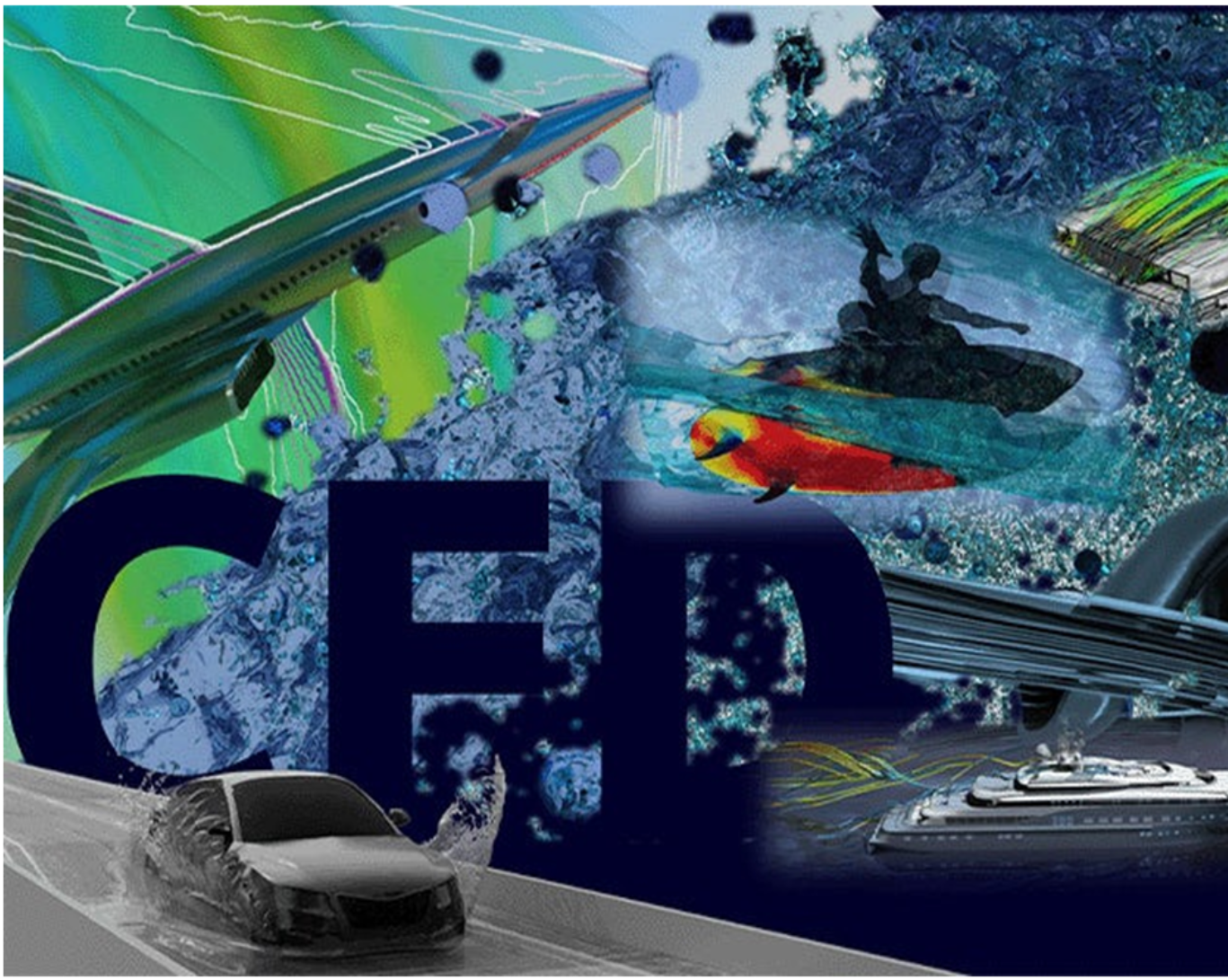

An Introduction to Computational Fluid Dynamics (CFD)

What is Computational Fluid Dynamics?

Computational Fluid Dynamics (CFD) is a branch of fluid mechanics that uses numerical analysis and algorithms to solve and analyze fluid flow problems. It is an interdisciplinary field that brings together computer science, applied mathematics, and engineering physics. CFD is a vital tool for engineers and scientists who study and design complex fluid systems in multiple industries.

The Convergence of Computers, Applied Mathematics and Physics

In recent years, the convergence of computer power, applied mathematics, and physics has allowed CFD to grow into a powerful tool for modern engineering. CFD, or computational fluid dynamics, is a field of study that uses numerical methods and algorithms to solve, predict and analyze problems involving fluid flows. The ability to simulate fluid dynamics, coupled with the rapid advancement in computer technology, has made CFD an indispensable tool in industries ranging from aviation to healthcare.

One of the key benefits of using CFD is the ability to simulate and optimize designs before they are physically built. This saves time and resources, as well as allowing for more complex and innovative designs to be tested. For example, in the aviation industry, CFD is used to simulate airflow around an aircraft and optimize its design for maximum efficiency and performance. This has led to the development of more fuel-efficient and environmentally friendly aircraft.

The use of CFD is not limited to large corporations and research institutions. With the availability of powerful and affordable computing resources, even small businesses and individual engineers can use CFD to improve their designs and products. This democratization of CFD has led to increased innovation and competition in many industries.

In conclusion, the convergence of computer power, applied mathematics, and physics has led to the development of CFD as a powerful tool for modern engineering. Its ability to simulate and optimize designs has led to more efficient and innovative products in industries ranging from aviation to healthcare. With the continued advancement of computer technology, CFD is poised to become an even more indispensable tool in the years to come.

How it Started

The origins of CFD dates back to the 1920s, where pioneering work by Leonard Euler and his equations describing how fluid flows were applied to aircraft wing design. Since then, the field has grown exponentially. With the advent of computers in the 1960s, numerical methods were developed to solve the set of partial differential equations that govern fluid flows.

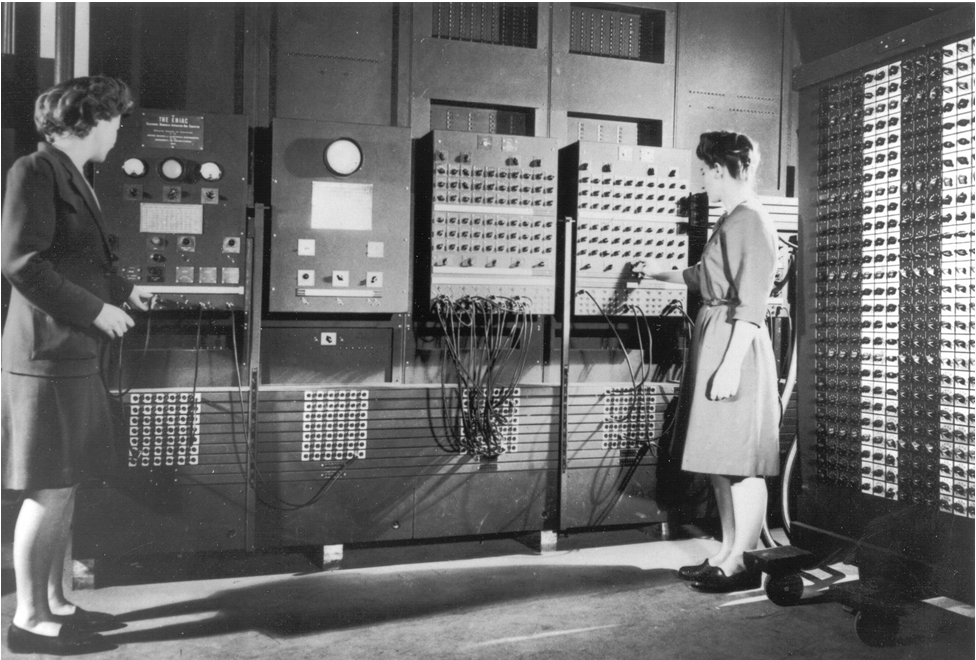

Programmers Betty Jean Jennings (left) and Fran Bilas (right) operate ENIAC's main control panel at the Moore School of Electrical Engineering. (U.S. Army photo from the archives of the ARL Technical Library). The ENIAC was used to perform some of the earlies computational fluid dynamics simulations under the leadership of famed fluid dynamicist John von Neumann.

The field of CFD has revolutionized the way we design and optimize fluid systems. From aircraft wings to wind turbines, CFD has played a crucial role in improving the performance and efficiency of various systems. CFD simulations have also been used to study natural phenomena such as ocean currents and atmospheric flows.

With the advancement of technology, CFD simulations have become more accurate and efficient. Today, CFD simulations can be performed on complex geometries with millions of grid points, giving engineers and scientists a detailed understanding of fluid behavior.

The development of CFD has not only impacted the field of engineering but has also led to the creation of new industries. The demand for CFD software and services has grown tremendously, leading to the emergence of companies specializing in CFD simulations. These companies offer CFD simulations as a service, allowing businesses to optimize their designs without having to invest in expensive software and hardware.

How It's Going

Today, Computational Fluid Dynamics (CFD) is a mature and rapidly advancing field with wide-ranging applications. Its development has been driven by the increasing need for efficient and effective simulations that can account for complex geometries and fluid behaviors. These simulations can predict the performance of complex systems while reducing the reliance on physical testing in turbulent conditions.

CFD has become an essential tool in the design and optimization of many products and systems, including aircraft, automobiles, ships, and buildings. In the aerospace industry, CFD is used to design and optimize the shape of wings, reduce drag, and improve fuel efficiency. In the automotive industry, CFD is used to optimize the design of engines, reduce aerodynamic drag, and improve vehicle safety. In the marine industry, CFD is used to design and optimize the shape of hulls, reduce drag, and improve fuel efficiency. In the building industry, CFD is used to optimize heating, ventilation, and air conditioning systems, and to predict the spread of smoke and fire in case of emergencies.

CFD simulations can also be used to study environmental problems, such as air and water pollution. They can help researchers understand the behavior of pollutants in the atmosphere and water bodies, and develop strategies to reduce their impact on human health and the environment.

CFD researchers and practitioners work in academia, government agencies, and private companies, and collaborate with experts from various fields to tackle real-world problems. For a look into what it means to be a CFD engineer, check out this podcast featuring Stewart Bible of Resolved Analytics.

As the demand for more efficient and sustainable products and systems continues to grow, the importance of CFD in the design and optimization process will only increase. With the development of new simulation methods and computing technologies, CFD will continue to push the boundaries of what is possible in fluid dynamics and beyond.

Who Uses CFD?

Computational Fluid Dynamics (CFD) is a powerful tool that has revolutionized the way engineers and scientists analyze fluid flows. CFD has influenced several industries, ranging from aerospace to biomedical engineering. In this section, we will explore some of the key industries that use CFD and how it has helped to improve their designs and products.

Aerospace Industry

Aerospace engineers use CFD to analyze aerodynamics, which helps to design better aircraft with reduced drag and fuel consumption. By simulating the flow of air over the wings, fuselage, and other components of the aircraft, engineers can optimize the design to minimize drag and improve lift. CFD has also been used to study the effects of turbulence and other complex flow phenomena on aircraft performance and aeroacoustics, which has led to the development of more efficient and quiet aircraft.

One of the most significant benefits of CFD is its ability to analyze airflow over a wing, which is crucial in designing an airplane wing. Traditionally, analyzing airflow over a wing can take months, but with CFD, it can take several hours. CFD enables engineers to test different wing designs and configurations quickly, which significantly reduces the design cycle time. This faster design cycle time allows engineers to create more efficient and safer airplane wings.

Automotive Industry

The automotive industry uses CFD simulations to optimize the aerodynamic design of cars, which aims to reduce drag, improve fuel economy and reduce carbon dioxide emissions. By simulating the flow of air over the car's body, engineers can identify areas of high drag and develop solutions to reduce it. CFD has also been used to study the airflow around the tires, brakes and side mirrors, which has led to the development of more efficient cooling systems and quieter rides. Additionally, CFD simulations have been used to analyze the internal flow of fuel and air in engines, which has led to the development of more efficient and powerful engines.

Biomedical Engineering

In biomedical engineering, CFD has been used to analyze the flow of blood in veins and arteries and help to develop treatments to fight heart diseases. By simulating the flow of blood through the arteries, engineers can identify areas of high turbulence and improve the performance of medical treatments for arterial diseases. CFD has often been used to study the effects of stents and other medical devices on blood flow, which has led to the development of more effective treatments for heart disease.

CFD simulations can also help identify causes of high blood pressure, which can lead to the development of aneurysms or other cardiovascular diseases, in a digital twin of the patient, leading to more personalized and effective medical interventions.

In conclusion, CFD is a powerful tool that has transformed the way engineers and scientists analyze fluid flows. Its applications are vast and varied, and it has helped to improve the designs and products in several industries. As technology continues to advance, we can expect CFD to play an even more significant role in shaping the future of engineering and science.

What Makes CFD a Niche Capability?

CFD, or computational fluid dynamics, is a highly specialized and technical field that has revolutionized the way engineers design and optimize fluid systems. It involves the use of sophisticated software tools and numerical methods to simulate and analyze the behavior of fluids in complex systems. CFD is a powerful tool that enables engineers to gain insights into the behavior of fluids in a wide range of applications, including aerodynamics, hydrodynamics, heat transfer, and chemical reactions.

One of the key advantages of CFD over physical testing is the ability to model larger scale systems accurately. This is particularly important in industries such as aerospace and automotive, where the cost and complexity of physical testing can be prohibitive. By using CFD, engineers can simulate the behavior of fluids in complex systems, such as an airplane wing or a car engine, and make informed decisions about design changes.

However, it is important to note that CFD is not a replacement for physical testing. While CFD can provide valuable insights into fluid behavior, it is still limited by the accuracy of the numerical methods and the assumptions made in the simulations. Physical testing is crucial to validate numerical simulations and ensure that the design meets the required specifications.

Despite its niche, CFD is an essential tool for engineers working in a wide range of industries. It enables them to make informed decisions about complex engineering problems while also being more cost-effective. CFD has become increasingly important in the design and optimization of modern engineering systems, and its use is expected to continue to grow in the future.

In conclusion, CFD is a highly specialized and technical field that has revolutionized the way engineers design and optimize fluid systems. It enables engineers to make informed decisions about complex engineering problems while also being more cost-effective. While it is a niche capability, its application is not limited to traditional engineering fields and is expected to continue to grow in the future.

Conclusion

In conclusion, CFD has transformed the way engineers approach fluid dynamics problems, allowing more accurate predictions to solve complex engineering problems. It has become an indispensable tool across multiple industries, providing tangible benefits such as faster design cycles, improved fuel efficiency, and better patient outcomes in the medical field. As technology continues to advance, we can expect CFD to play an even more critical role in solving complex engineering problems and improving our world.

Image Meta: Discover the world of Computational Fluid Dynamics and its importance in engineering and scientific research.