Co-Sourcing - An Increasingly Utilized Model for Addressing Computational Engineering Needs

Given the nature of our work we've become quite familiar with the in-source versus out-source debate as it applies to computational engineering services. What we've learned over the years is that no two businesses are identical and that a thorough understanding of a company's core business is key to making any sourcing decision. When the topic comes up we always start with a discussion of the benefits of in-sourcing because it is the more familiar of the two strategies.

The Intuitive Advantages of In-Sourcing

The most intuitive argument for in-sourcing is that it can help companies build strong, talented teams which are inherently attuned to company-specific objectives and will naturally promote the company’s core values through their work. In-sourcing can also keep companies focused on the in-house skills and expertise that make them stand-out from their competitors. For example, Apple would have been crazy to out-source product design but did well to out-source the lion's share of their product manufacturing, And still in other cases, a company's sense of tradition and loyalty to longstanding members of their support services team or high levels of IP sensitivity may steer them towards the in-sourced model.

Based on current trends, though, such motivations are becoming the exception rather than the rule. Ever more frequently companies tell us that they are focused less on employee skills and expertise as core competencies and more on efficiently achieving their key strategic goals and objectives of the company.

But What, Exactly, is Co-Sourcing?

Co-sourcing is becoming increasingly synonymous with forming ad hoc teams of internal and external specialist working together to solve complex challenges. Co-sourcing is a partnership between a customer and a professional service provider. A company chooses the vendor, which works with and often alongside—but doesn't replace—the existing staff, based on specific skills needed to get the job done. When the project is finished, the professional service firm's job is over, too.

Co-sourcing can allow an in-house team to retain responsibility for internal processes while relying on an outside entity for specialized technical skills and personnel that are more effectively maintained by an organization who provides these services as part of their core business. These co-sourced services help companies avoid hiring directly and alleviate the burdens of training and paying benefits for resources that are only partially utilized.

Co-sourcing has clear cost and scale advantages and managed correctly it will let you refocus your organizations resources on areas that drive growth.

— Matthew Griffin - Business Advisor in Emerging Technology and Business Disruption

The Only Thing Certain in Life is Change

If the transition from in-sourcing to co-sourcing is managed correctly then the advantages can be quickly realized, not only in terms of potential cost savings, synergies, and efficiencies, but also in the quality of service delivery. For an organization considering the journey of moving from an in-sourced model to a co-sourced model, what does the process look like? The following is our suggested step-by-step approach.

Step 1 — Perform a cost/quality analysis of currently in-sourced engineering services and potential impacts of co-sourcing.

Step 2 — Identify the cultural and human impact of change (both positive and negative).

Step 3 — If Steps 1 & 2 are encouraging, create a project specific scope of work and issue requests for proposals to service providers.

Step 4 — Based on responses, project specific quality and cost benefits to your business.

Step 5 — Improve existing operations or engage with service provider.

Step 6 — Establish mutual and joint objectives and maintain focus on these throughout the project.

Step 7 -- Quantify the project successes and tangible business improvements realized as a result of the project

Remember, it is both the client’s and the vendor’s responsibility to ensure that they are both on the same page and focused on the positive outcomes needed to demonstrate that this is a joint partnership intended to improve the client’s overall business and, therefore, ultimately of benefit to all its stakeholders, employees, and partners.

Getting Started on Step 1

Often we come across clients who don’t know what their precise costs are for currently in-sourced CFD and other computational engineering services they utilize. This lack of cost awareness is very common and can happen for a number of reasons including, most frequently, non-transparent departmental budgets. To help tackle this missing baseline we have recently examined the annual costs associated with maintaining a typical, industrial level of internal CFD capabilities, including hardware, software, and personnel costs. Personnel costs include that of a CFD engineer but ignores any potential IT personnel costs associated with maintenance of the software and hardware required.

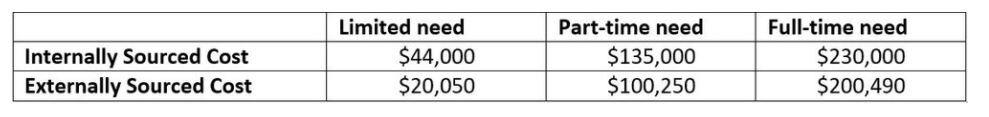

For a rough estimation of in-sourcing versus co-sourcing costs, we analyze the following CFD usage scenarios.

Full-time need: Your company has CFD demands that will fully utilize a dedicated CFD engineer.

Part-time need: Your company has CFD demands that will utilize the CFD engineer at a 50% rate.

Limited need: Your company only has the occasional need for CFD that will utilize a generalist engineer at a 10% utilization rate.

And we assume the following.

An internal CFD engineer salary of $95,000.

A corporate overhead multiplier of 2.0.

An overall 75% utilization rate of an engineer’s hours (subtracting vacation, holidays, admin time, etc), implying a full-time need is for 1560, a part-time need is for 780, and a limited need is for 156 engineering hours.

An outside consultant, fully-weighted (including overhead and profit) rate of $140/hr.

A CFD annual cost of $40k (comprehensive package) in the full and part time need cases.

A CFD annual cost of $25k (CAD integrated package) in the limited need case.

An outside specialist is able to complete the work in 10% fewer hours than internal resources.

The overhead required to manage the outside consultant adds 2% additional internal hours.

The results of the analysis shown in the following table are surprising to some. Even in the case where CFD workloads require a full-time, dedicated CFD engineer, co-sourcing is the more cost effective approach.

Where to go from here?

We suggest considering the quality aspect of working with a team such as ours that is completely focused on computational simulations on a 24-7 basis. Extend the cost analysis outlined above to your own organization, and reach out to us. Together we can work towards a conclusion regarding whether co-sourcing is the right choice for you, including a fixed or variable cost proposal to suit your needs.