A Guide to Estimating the Organizational Costs of Computational Fluid Dynamics (CFD) Simulations

CFD COSTS

Table of Contents

This guide will walk you through the process of estimating costs associated with Computational Fluid Dynamics (CFD) simulations.

Understanding Your Needs

Software & Hardware Costs

Personnel Costs

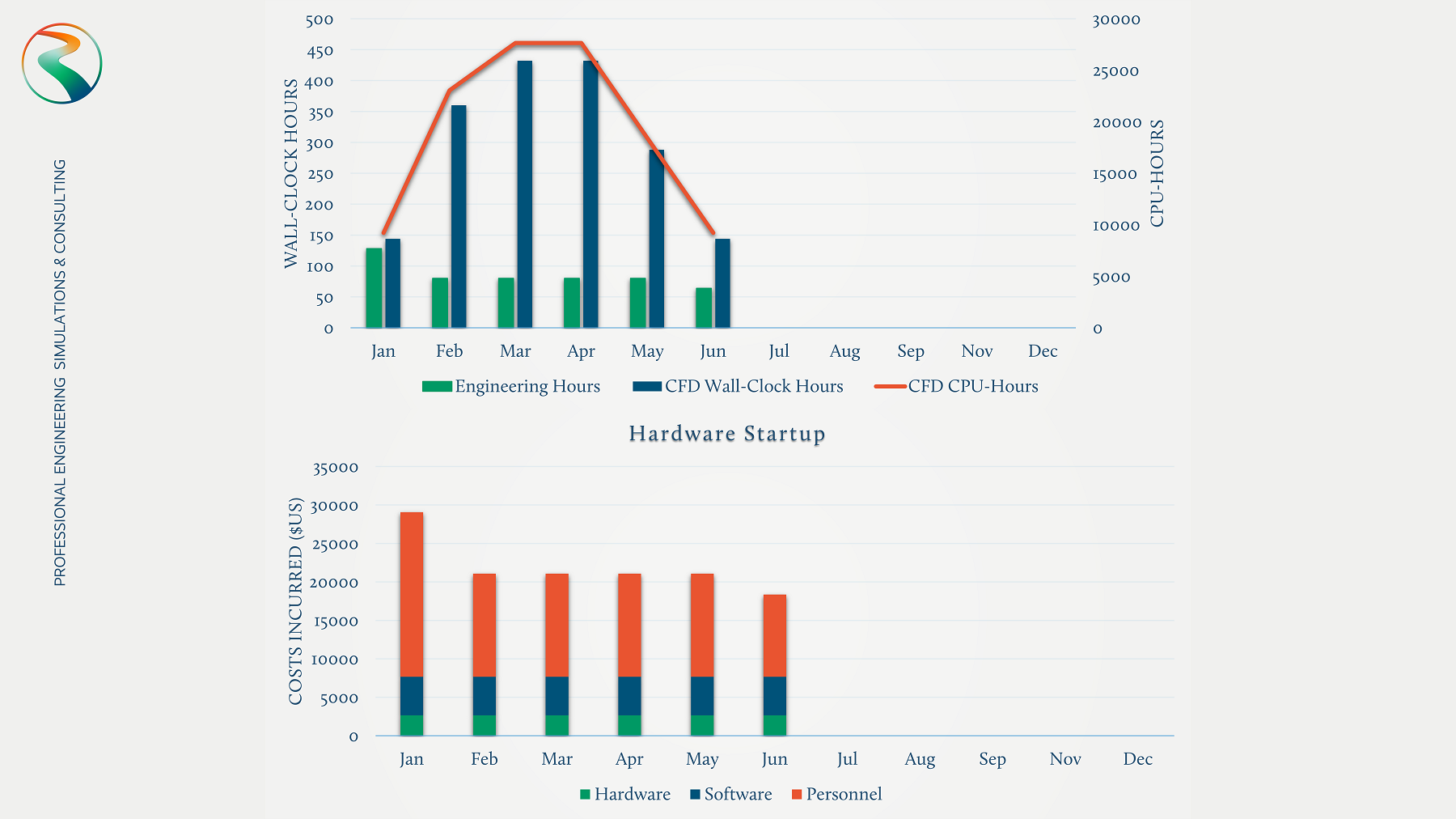

Use Case: Technology Developer

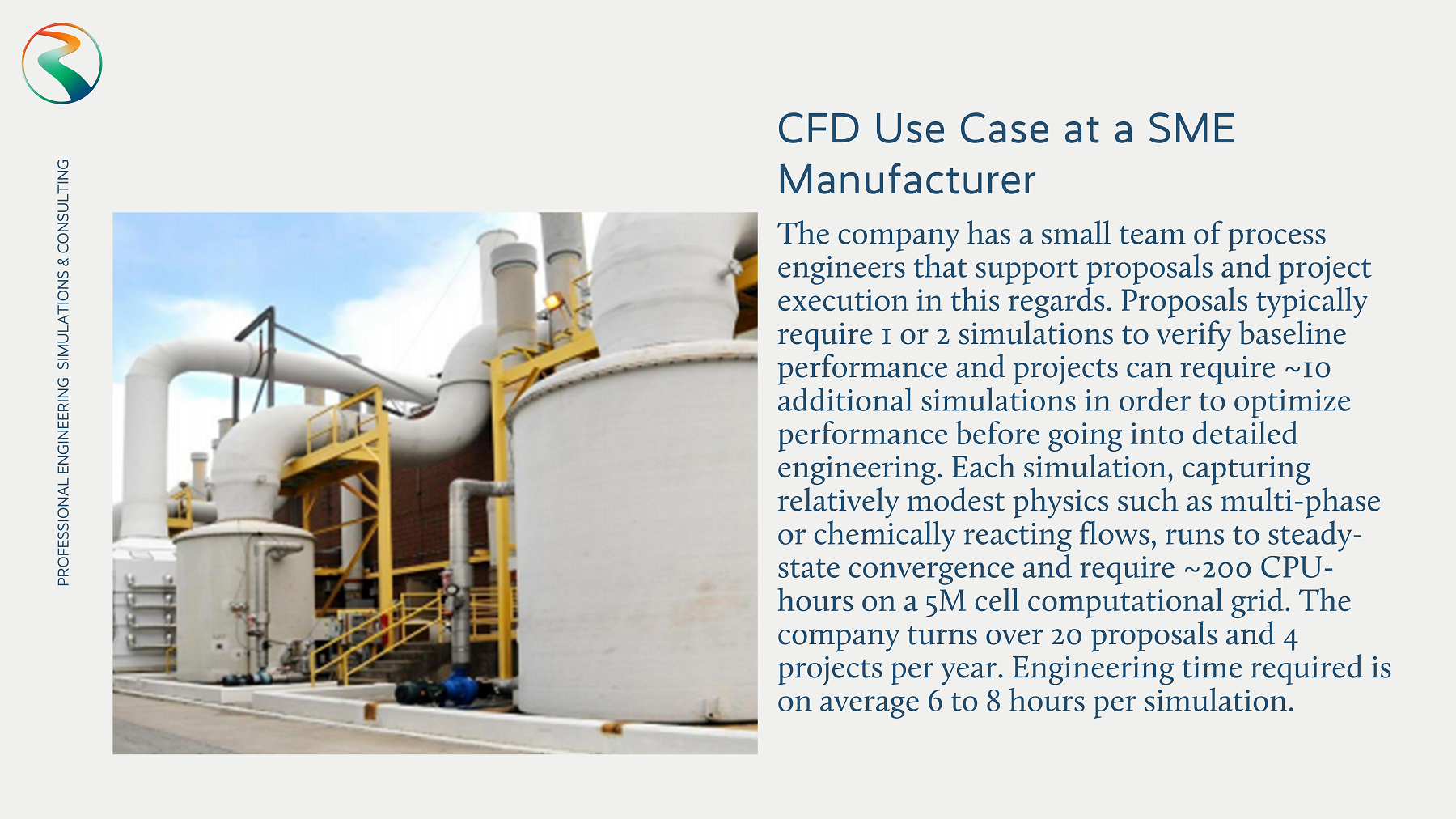

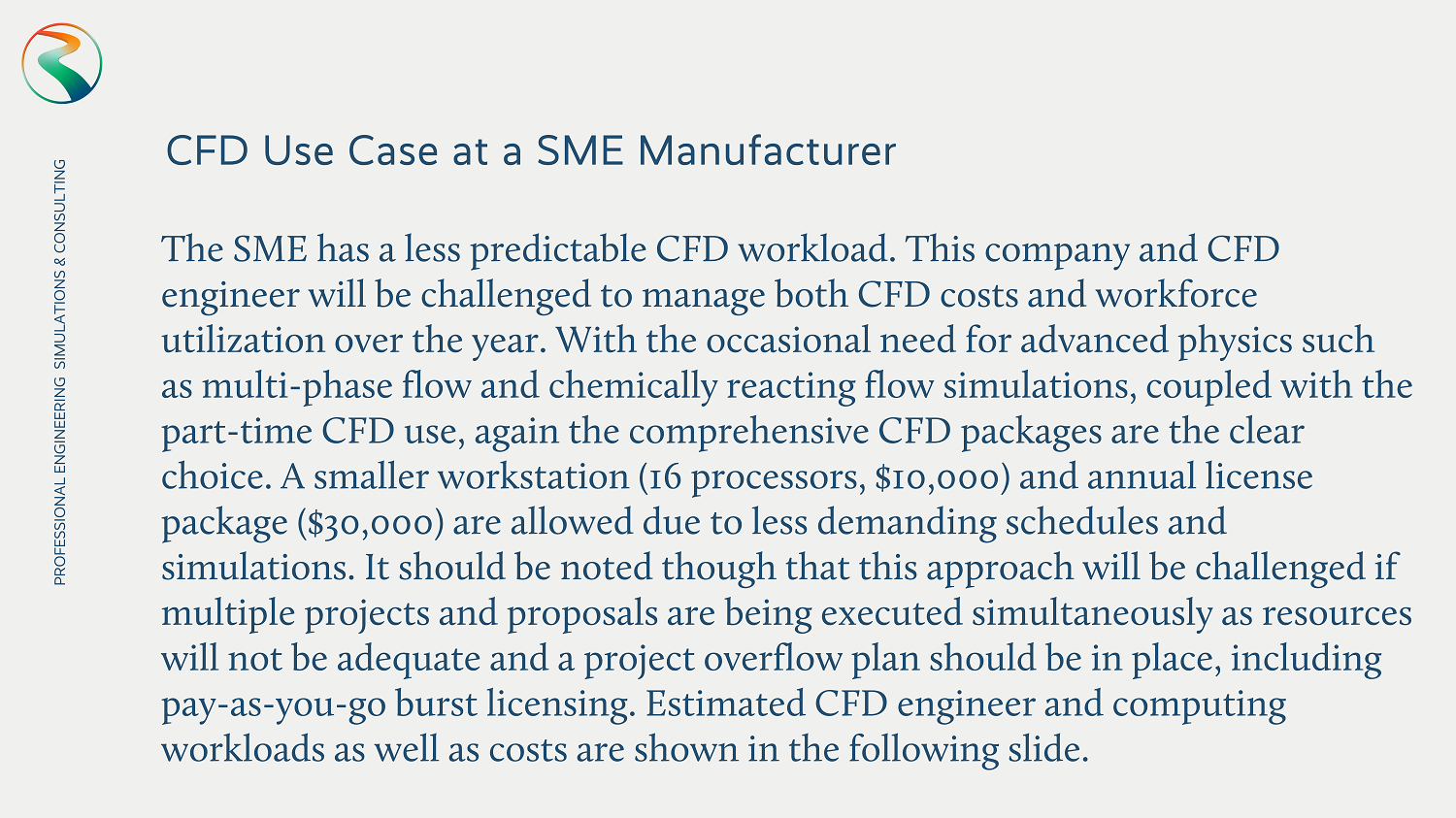

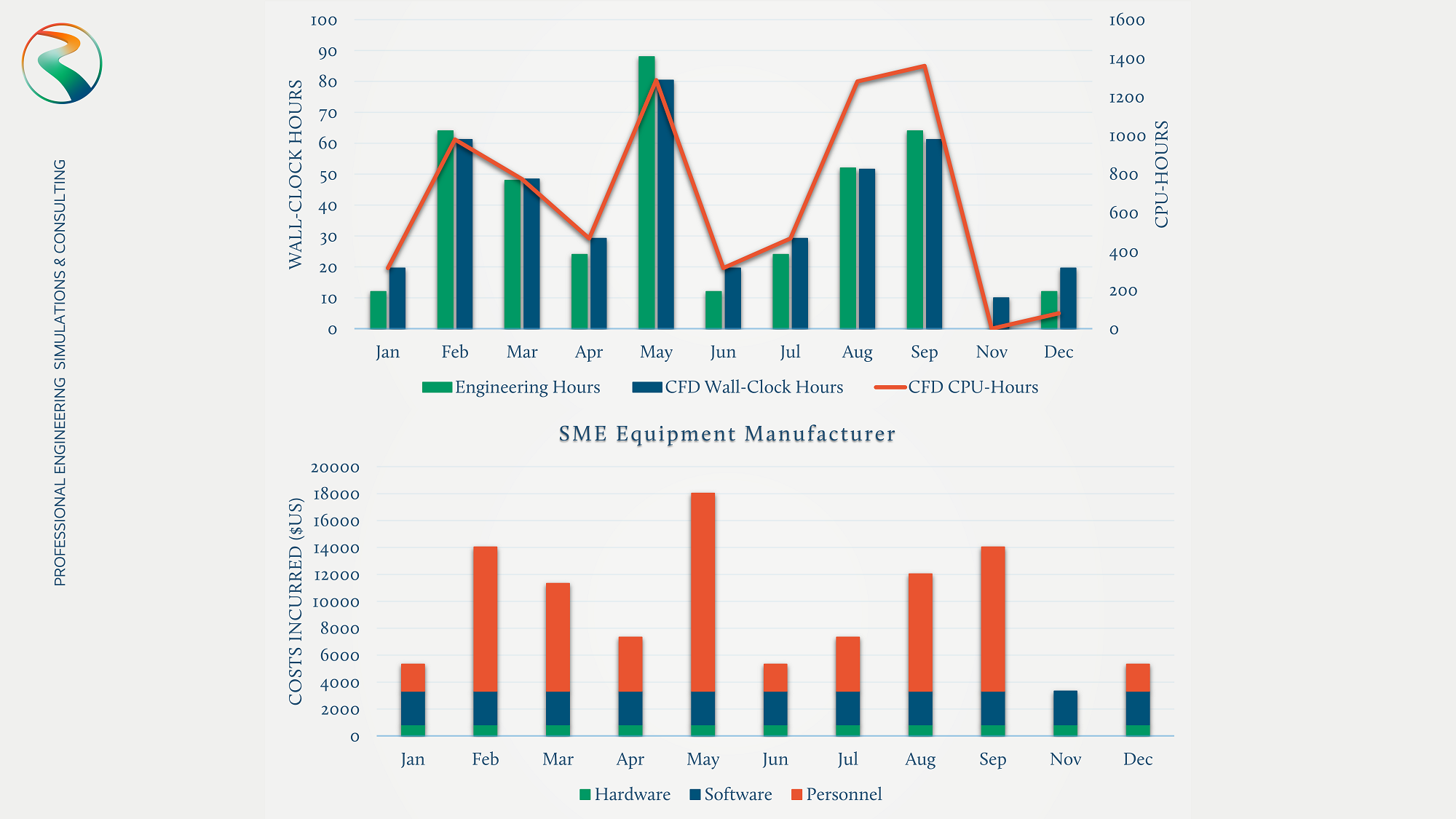

Use Case: SME Manufacturer

Co-sourcing: A Cost-Effective Option

While the use case and needs analysis will provide the basis of a CFD acquisition strategy, there are several potential hardware, software, and manpower combinations that can meet any simulation requirement.

Understanding Your Needs

Understanding Your Needs

It’s no secret that CFD and other forms of computational engineering provide a competitive edge, but knowing how your organization will leverage simulation is critical to understanding future costs.

What Determines Your Needs?

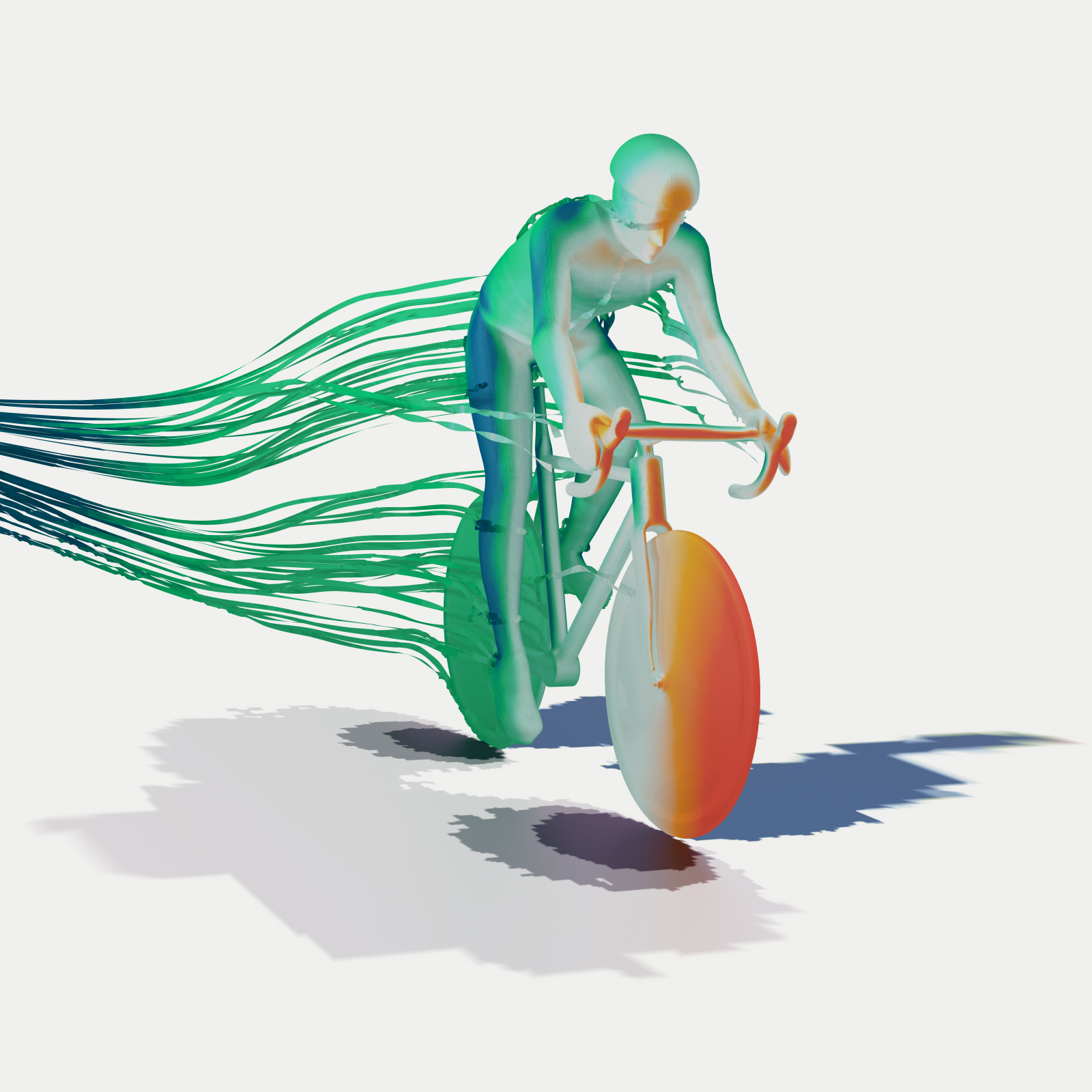

The business case for computational engineering simulation tools such as CFD is very company specific. Most commonly, value is derived by reducing time to market with new or improved products and lowering the costs of development by reducing the need for physical prototyping. The effort and resources that will be required in such a program is strongly dependent upon the number of products in the development cycle, the targeted performance levels, and the company’s skill in applying simulation technology.

Software and Hardware Costs

Software and Hardware Costs

Match Your Physics Needs, Team Capabilities, and Budget

You can also read our 5-part series on Comparing CFD Software in which we’ve broken down some of the more widely used packages and their capabilities based on a combination of first-hand experience, research, and user surveys.

Finding the software package that fits your company.

CFD software packages generally fall into one of the following five broad categories; opensource, open-source wrappers, CAD integrated, specialty, or comprehensive. Your needs analysis, personnel capabilities, and cost considerations will drive decision making. The physics you need to simulate in order to achieve your project objectives is a relatively simple filter to apply that should help reduce the number of options available to you right away. For example, if you are intending to model open-surface flows, your options are quickly reduced to only those codes able to perform Volume-of-Fluid (VoF) calculations. Most software companies do a good job of describing what physics they are capable of modeling.

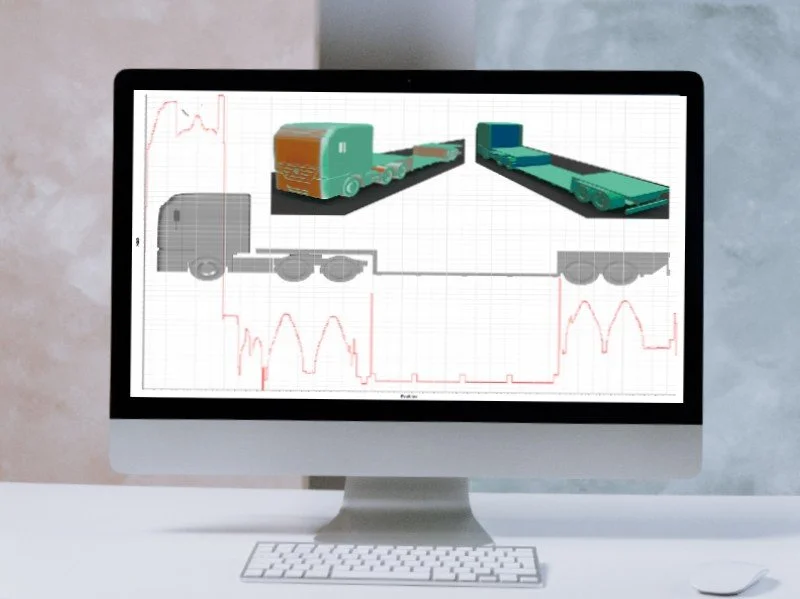

Estimating Software & Hardware Costs

A second filter that can be applied is that of personnel capability. Open-source solutions are well-known for their cost-effectiveness at scale but are also equally well-known for their lack of ease of use. The most common open-source software, Open-FOAM, is command line and text file driven, lacking either native pre- or post-processing Graphical User Interfaces (GUIs) and is currently only available for Linux operating systems. Users without the patience for the workflow disruptions that result or the skill to overcome common challenges in these regards are advised to steer away from open-source software.

Commercial licensing costs are highly variable with product sophistication, estimated to fall in the broad range between $10 and $35 per hour per active simulation. High-fidelity models running in parallel across dozens of cores are in the higher end of this range. Cloud based licensing aligns closely with this pricing band. Hardware costs are estimated between $0.05 and $0.20 per cpu-hr and include costs from power, cooling, and depreciation. Though hardware costs continue to decrease over time, they can still represent a substantial upfront cost when needs require a small CFD cluster or top-end workstation. Several cloud computing service providers now exist that can lower or eliminate the need for upfront capital expenses and some commercial CFD software companies can now be accessed as a pay-as-you-go resource, which is convenient for teams with variable or project-based workloads.

Personnel Costs

Personnel Costs

CFD simulations demand highly skilled engineers, significant planning effort, and careful resource utilization. With salaries, overhead, and IT support included, engineering labor often represents the largest portion of CFD program expenses.

Personnel costs make up the majority of CFD cost ownership.

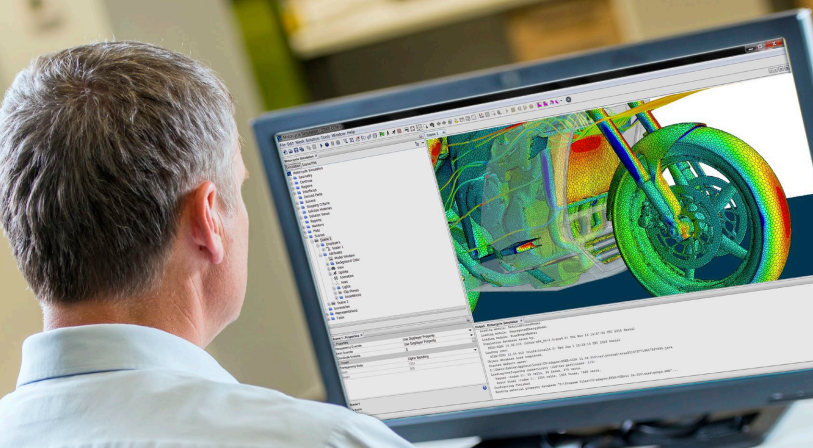

CFD simulations are personnel intensive. The effort level that is required is dependent upon the complexity of the simulations needed, the acumen of the simulation engineer, the software and hardware used, and the documentation requirements. A qualified CFD engineer has an advanced degree in an engineering discipline and more than 5 years of experience in applying CFD to industrial scale problems. Using their expertise, they will not only perform analyses but will also provide leadership in advancing company goals, planning, and coordinating analyses in order to meet company objectives. A CFD engineer’s workload can be erratic. Most of the effort in a study is spent initially in understanding project objectives, planning the analysis process and outputs, and setting up initial simulations. After submitting a simulation for execution, the simulation engineer must then sit and wait for a result. In some cases where simulations take multiple days, it is important for the CFD engineer to be post-processing previous runs or pre-processing future runs in order to maintain a high utilization rate.

Becoming highly skilled in balancing workloads with hardware and software resources takes many years of practice. In addition, if CFD requirements are up and down throughout a year, CFD engineers may face extended periods where these skills are not being used. Engineers must be multifaceted, and companies must be creative in their use of this downtime in order to maintain respectable rates of utilization. In our experience, a utilization rate of ~80% is about as high as can be expected. After subtracting standard vacation and other administrative tasks, overall utilization rates of ~60% are expected. With a representative salary of $95,000 / year, and a typical company overhead ratio of 2.0, it is obvious that CFD engineering personnel costs make up the majority of the total cost of ownership of CFD. In addition, IT personnel will be needed to maintain internal or external computing resources and software. A representative IT cost of 10% of CFD engineer costs is assumed here.

Co-Sourcing: A Cost-Effective Option

Co-Sourcing: A Cost-Effective Option

Given the high costs of ownership associated with CFD, it is natural to ask if out-sourcing, or, more appropriately, co-sourcing of CFD is the optimal solution for some companies.

What is Co-Sourcing?

Co-sourcing is the act of forming ad hoc teams of internal and external specialist working together to solve complex challenges. Co-sourcing is a partnership between a customer and a professional service provider. A company chooses the vendor, which works with and often alongside—but doesn't replace—the existing staff, based on specific skills needed to get the job done. When the project is finished, the professional service firm's job is over, too.

Co-sourcing can allow an in-house team to retain responsibility for internal processes while relying on an outside entity for specialized technical skills and personnel that are more effectively maintained by an organization who provides these services as part of their core business. These co-sourced services help companies avoid hiring directly and alleviate the burdens of training and paying benefits for resources that are only partially utilized.

“Co-sourcing has clear cost and scale advantages, and managed correctly, it will let you refocus your organizations resources on areas that drive growth.”

-Matthew Griffin, Business Advisor in Emerging Technologies