From Boeing to Boom – CFD for Aerospace Aerodynamics

In the aviation industry, predicting airframe aerodynamics and reducing time to market with new designs are critical factors in producing successful aircraft. Over the past 50 years, NASA and Boeing have been at the forefront of aerodynamics analysis, pioneering new methods to streamline the design process and enhance aero efficiency. Today, new players, such as Boom Supersonic, are leveraging advanced technologies to take commercial aviation to new heights. Let's explore the evolution of aerospace engineering, the basics of aerodynamics and its pioneers, the role of software in streamlining design processes, and Boom Supersonic's vision for the future of supersonic commercial travel.

What is Aerodynamics?

Aerodynamics is the study of how air flows around objects and the forces created by that flow. By understanding the flow patterns and forces, engineers can design aircraft, cars, buildings, and other objects that slice through the air efficiently and with control. In essence, aerodynamics allows us to bend the flow of air to our needs and desires.

What are the Four Laws of Aerodynamics?

1. The law of lift: A wing produces lift due to the difference in air pressure above and below it.

2. The law of drag: Any object moving through the air experiences drag, which opposes its motion.

3. The law of thrust: To maintain or increase speed, an object must be propelled forward by a force called thrust.

4. The law of weight: The weight of an object affects its ability to fly, with heavier objects requiring more lift to stay aloft.

One of the fundamental concepts of aerodynamics is the four forces of flight: lift, weight, thrust and drag. These forces act on any object that moves through the air, such as an airplane, a rocket, a kite or a bird. To fly, an object must balance these forces in a way that allows it to overcome gravity and air resistance.

Lift is the force that pushes an object upward. It is generated by the shape the airplane’s wings, airfoils, winglets, flaps, slats or other surfaces that interact with the air.

Weight is the force that pulls an object downward. It is determined by the mass of the object and the gravity of the planet or moon it is on.

Thrust is the force that propels an object forward. It is produced by engines or propellers that push air or fuel behind them.

Drag is the force that resists an object's motion through the air. It is caused by friction and pressure differences between the front and back of the airplane.

The Practice of Aerodynamics

Early methods of predicting airframe aerodynamics used by industry pioneers, going all the way back to the birthplace of aviation in Dayton Ohio, were primarily empirical. Pioneering aerodynamicists, such as the Wright Brothers, relied heavily on wind tunnel testing and flight testing. The Wright Brothers, self-taught in aerodynamics, built one of the earliest wind-tunnels for testing lift and drag of potential airfoil designs, a replica of which is shown in the image below.

What is an airfoil (or aerofoil)?

An airfoil is a collection of surfaces defining a 3d body shaped in such a way that the air flow around it produces a desired aerodynamic effect, such as lift.

Airfoils used in airplane wings are often shaped to produce higher relative air velocity on the top of the wing and slower relative air velocity on the bottom of the wing. The faster air produces lower pressures on the top of the wing versus the slower air on the bottom of the wing, according to Bernoulli’s Principle. This dynamic produces a net upward “lift” force on the wing.

The Origins of Airfoil Studies

In 1915, 12 years after the Wright Brothers made mankind’s inaugural flight in Kitty Hawk NC, the United State Congress established the National Advisory Committee for Aeronautics (NACA) with the purpose “to supervise and direct the scientific study of the problems of flight, with a view to their practical solution.”. Central to NACA’s work was the variable density wind tunnel at the Langley Memorial Aeronautical Laboratory, in which NACA engineers and scientists began testing known airfoil shapes from all over the world in the mid-1920s. Although the work was somewhat random in nature, NACA made the first attempts at systematically defining airfoils through parameters such as chord, camber, and thickness. A few of these are shown in the graphical representation of an airfoil below.

However, challenges with empirical methods arose due to the high cost and limited accuracy of these methods. Engineers and scientists were forced to rely on limited data to make important decisions about aircraft design and performance.

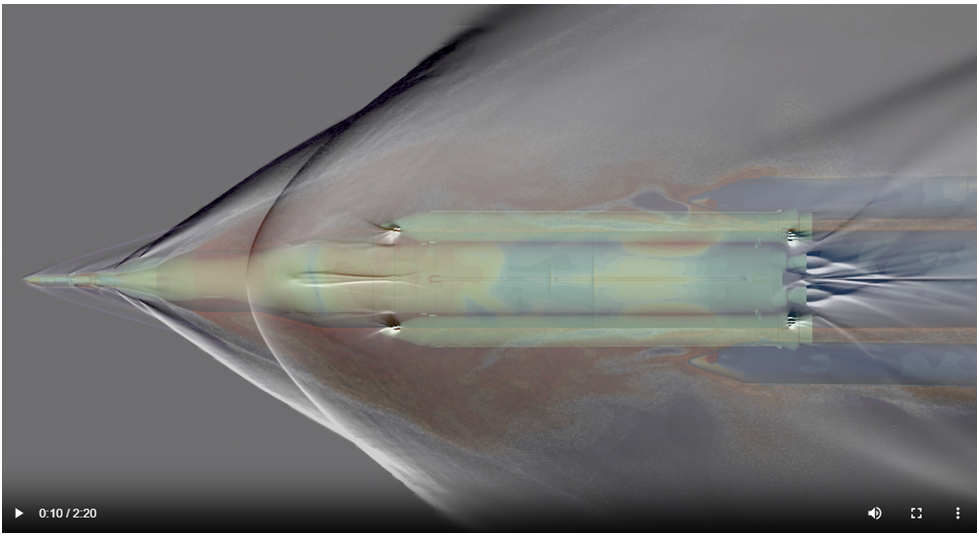

As the aviation industry grew, so too did the need for more accurate and efficient methods of predicting airframe aerodynamics. The introduction of computational fluid dynamics (CFD) in the 1970s revolutionized the industry, providing a new way to model air movement around complex aircraft designs with far greater accuracy. CFD uses mathematical algorithms to simulate the flow of air around an aircraft, taking into account factors such as air pressure, temperature, and velocity. It is also known for producing compelling visualizations that provide intuitive insight into aerodynamics, as demonstrated in the video below.

With the advent of CFD, engineers and scientists could create virtual wind tunnel tests, allowing them to test and analyze designs without the need for physical wind tunnels. This not only saved time and money, but also allowed for a greater range of designs to be tested and analyzed. CFD also allowed for the analysis of complex flow phenomena, such as turbulence and boundary layer separation, which were difficult to study using traditional wind tunnel testing.

Today, advancements in simulation technology are being leveraged to model aerodynamics virtually, reducing the reliance on physical testing and significantly shortening the design cycle. High-performance computing and artificial intelligence are being used to create more accurate and efficient simulations, allowing engineers to quickly and accurately analyze a wide range of design options.

As the aviation industry continues to evolve, the importance of accurate and efficient airframe aerodynamics prediction will only continue to grow. With the help of advanced simulation technology, engineers and scientists will be able to design aircraft that are more efficient, safer, and more environmentally friendly than ever before.

NASA's Pioneering Role in Aerodynamics Analysis

In July of 1958, US President Dwight Eisenhower signed into law the National Aeronautics and Space Act, officially transforming NACA into a new entity; the National Aeronautics and Space Administration, or NASA. NASA has been at the forefront of aerodynamics research and development ever since. NASA researchers have made major contributions to the field of aerodynamics that have improved our understanding of flight and our ability to travel through the air and beyond.

NASA has contributed extensive research and development in the four forces of flight: lift, weight, thrust and drag.

In the area of lift, NASA has studied how different airfoils, winglets, flaps and slats, affect the amount and direction of lift. NASA has also investigated how factors such as air density, speed, angle of attack and downwash influence lift. In the area of weight, NASA has developed methods to measure and control the weight and center of gravity of aircraft and spacecraft. NASA has also explored how weight affects the performance and stability of flying vehicles. In the area of thrust, NASA has experimented with different types of engines and propellers, such as jet engines, rocket engines, turboprops, turbofans and electric motors. NASA has also tested how thrust affects the speed, range and fuel efficiency of aircraft and spacecraft. In the area of drag, NASA has examined how different shapes, sizes and orientations affect the amount of drag on an object. NASA has also measured how drag varies with air density, speed, viscosity and turbulence.

NASA's pioneering role in aerodynamics has not only advanced our scientific knowledge, but also our practical applications. NASA has used its expertise in aerodynamics to design and develop various aircraft and spacecraft that have achieved remarkable feats and benefits for humanity. NASA’s Common Research Model (CRM), a design collaboration with Boeing coupled with several exquisite wind tunnel models as shown below, has enabled many formal and informal cooperative research studies between international organizations in government, industry, and academia.

Another example of NASA leadership in aerospace engineering is the Space Shuttle program, which ran from 1981 to 2011. The Space Shuttle was a reusable spacecraft that could launch like a rocket, orbit like a satellite, and land like an airplane. It was used for many missions, such as deploying satellites, repairing telescopes, conducting experiments, building the International Space Station (ISS), and carrying astronauts and cargo. The Space Shuttle was a complex aerodynamic vehicle that had to withstand extreme temperatures, pressures and forces during launch, reentry and landing. NASA used its knowledge of aerodynamics to ensure the safety and success of each mission.

Another example is the X-plane program, which started in 1946 and continues today. The X-planes are experimental aircraft that test new technologies and concepts in flight. They are used to explore the limits of speed, altitude, maneuverability, stealth, efficiency and more. Some of the most famous X-planes include:

- The X-1, which was the first aircraft to break the sound barrier in 1947.

- The X-15, which was the fastest and highest-flying manned aircraft ever, reaching speeds of over 4,500 mph and altitudes of over 350,000 feet in the 1960s.

- The X-29, which had forward-swept wings and a computerized flight control system that made it highly maneuverable and agile in the 1980s.

- The X-43A, which was the first aircraft to fly at hypersonic speed (over Mach 5) using a scramjet engine in 2004.

- The X-57, which is the first all-electric airplane that aims to demonstrate improved efficiency and reduced noise and emissions.

These are just a few examples of the many aircraft and aerospace vehicles that NASA has developed and flown over the years. Each one has contributed to advancing our knowledge and capabilities in aerodynamics and aerospace engineering.

NASA Knows CFD

With a history as described above steeped in empirical studies and wind tunnel testing, NASA was well aware of the challenges that CFD could potentially eliminate in aerodynamics research. For instance, it takes time to repeatedly attach string or set up a smoke wand in a wind tunnel, while a CFD can run certain visualizations in a minute or two — at any time. That is why they have played a leading role in CFD research and development as well as integrating CFD into airframe design and new product development.

Today, NASA engineers take a balanced approach to CFD and wind tunnel testing. While the number of operational wind tunnels is decreasing overall, NASA recently broke ground on a state-of-the-art vertical wind tunnel and continues to push the boundaries in computational fluid dynamics.

CFD Simulation of a Urban Mobility Aerospace Vecicle (courtesy of NASA)

NASA has played a pioneering role in aerodynamics since its establishment and continues to explore the frontiers of aerodynamics and push the boundaries of flight. NASA's motto is "For the Benefit of All", and its work in aerodynamics exemplifies that vision.

Boeing's Pioneering Role in Aerodynamics Analysis

The Boeing Company is one of the world's leading aerospace manufacturers, having developed and sold hundreds of billions of dollars of commercial airplanes over the last 30 years. This success has been built on a history of innovation and excellence in aerodynamics.

Boeing has been at the forefront of aerodynamics analysis for over half a century. In the 1950s, the company developed the first wind-tunnel specifically designed for commercial aircraft, giving it a significant advantage in developing more efficient and innovative aircraft designs. This innovation paved the way for the development of some of the most iconic planes in aviation history, including the Boeing 747 often referred to as the original jumbo jet.

One of the most significant contributions made by Boeing to the field of aerodynamics was the introduction of the swept-wing design in the 1960s. This design was first implemented in the Boeing 727, which was designed to be more fuel-efficient and stable than previous aircraft. The swept-wing design allowed the aircraft to fly at higher speeds with less drag, resulting in significant fuel savings and improved performance.

The success of the 727 led to the development of the Boeing 747, which featured a high aspect ratio and a wing with an upsweep. The 747 was the first jumbo jet and quickly became an icon of aviation. Its innovative design allowed for greater passenger capacity and longer range, making it a game-changer in the aviation industry.

The 787 Dreamliner program, which started in 2004 and continues today, is another example of Boeing’s leadership in aerodynamics. The 787 Dreamliner is a wide-body passenger jet that features many innovations in aerodynamics, such as a composite fuselage, raked wingtips, chevron engine nozzles and a high aspect ratio wing. These features reduce the drag and increase the lift of the airplane, making it more fuel efficient and environmentally friendly. The 787 Dreamliner also has a state-of-the-art flight deck that features large flat panel displays, dual head-up displays, and dual electronic flight bags. The 787 Dreamliner offers a superior passenger experience with larger windows, lower cabin altitude, higher humidity, smoother ride and enhanced lighting and entertainment systems.

A more “other worldly” example is the X-37B Orbital Test Vehicle program, which started in 1999 and continues today. The X-37B is a reusable unmanned spacecraft that can launch like a rocket, orbit like a satellite and land like an airplane. It is used for various classified missions by the U.S. Air Force and NASA, such as testing new technologies, conducting experiments and performing reconnaissance. The X-37B is a highly aerodynamic vehicle that has a lifting body design, a low-drag empennage, a high-temperature thermal protection system and a solar array for power generation. The X-37B can perform autonomous reentry and landing, using its aerodynamic control surfaces and thrusters to steer and decelerate.

Boeing's research into aerodynamics has had a profound impact on the aviation industry, influencing the design of aircraft around the world. The company's commitment to innovation and efficiency has led to more cost-effective and safe air travel, benefiting both the industry and passengers alike. From the first commercial jet airliner to the latest advancements in autonomous flight, Boeing has been at the forefront of innovation in the aviation industry for decades and has made it a trusted name in aviation around the world. We are sure that its legacy will continue to inspire and shape the future of aviation for generations to come.

The Role of Engineering Software in Streamlining Design

Today, software plays a critical role in streamlining the design process for airframe aerodynamics. Computer-aided design (CAD) software allows designers to create digital 3d models of aircraft designs, which can be easily modified and tested virtually. This allows designers to quickly identify design flaws and make adjustments before creating a physical prototype, saving both time and money.

In addition to CAD software, computational fluid dynamics (CFD) software is now also routinely used in the design process. CFD software allows engineers to simulate the flow of air around the aircraft and predict its aerodynamic performance. This is especially important for aircraft design, as even small changes to the shape of the aircraft can have a significant impact on its performance.

Boeing is well known as one of the most aggressive early adopters of CFD technology. Boeing engineers realized earlier than most that computational simulations could provide complementary functions to traditional physical models and flight testing, shortening the design cycle time significantly. Boeing ramped up CFD simulation capabilities faster than any other commercial entity, growing from performing a few hundred simulations per year in the early 1970s, to over 20,000 CFD cases per year by the early 2000s.

Boeing’s experience is that CFD has had its greatest impact on the aerodynamic design of the high-speed cruise configuration of transport aircraft. For example, the design of the Boeing 777, developed in the early 1990s at the time that CFD was becoming more widely applicable due to advances in computing power, proved an excellent demonstration of the utility of CFD. In that case, CFD simulations provided insight and augmented wind tunnel testing in almost every aspect of aerodynamic design, including; wing design, cab design, fuselage design, and assessing airframe life and drag characteristics.

NASA has also been a leading proponent, and critical assessor of Computational Fluid Dynamics. Recently, NASA’s Aerosciences Evaluation Test Capabilities (AETC) division has is investing in a capability challenge designed to assess the ability of CFD to address aeroscience prediction requirements at high supersonic speeds. To do this, a series of CFD analyses and wind tunnel tests will be conducted and compared to determine the accuracy of CFD.

The integration of simulation and testing has become increasingly important for predicting aerodynamic performance. By combining simulation models with real-world measurements, engineers can obtain a more accurate picture of how air moves around the aircraft. This allows for more precise design adjustments and ultimately leads to better overall performance.

One of the most exciting developments in this area is the use of digital twins. The idea of a “digital twin” was born at NASA in the 1960s as a “living model” of the Apollo mission. These virtual models replicate the physical aircraft to an extent that tests and simulations can be carried out digitally. As a result, design iterations can be made more quickly and accurately, significantly reducing the time to market for new aircraft. Digital twins are also connected to their physical counterparts to provide data feedback and updated assessments. This was key to the success of the Apollo 13 mission. Even though the Apollo 13 mission occurred 3 decades before the term “digital twin” was coined, it still stands out as one of the best real-life examples of a digital twin in action.

Another benefit of using software in the design process is the ability to collaborate more easily. Designers and engineers can work on the same digital model from different locations, making it easier to share ideas and make changes in real-time. This has led to more efficient and effective design processes, with less time and resources wasted.

Overall, the role of software in streamlining the design process for airframe aerodynamics cannot be overstated. From CAD software to CFD simulations and digital twins, these tools have revolutionized the way aircraft are designed and tested. As technology continues to advance, we can expect even more exciting developments in this field in the years to come.

Boom Supersonic and the Future of Airframe Aerodynamics

Boom Supersonic is a relatively new player in the aviation industry, but it is already making waves with its vision for supersonic commercial travel. The company is developing a supersonic transport aircraft capable of flying faster than the speed of sound, reducing long-haul flight times by up to 50%. This breakthrough in aviation technology has the potential to revolutionize the way we travel, making the world a smaller place and bringing people closer together.

One of the biggest challenges of supersonic aerodynamics is the intense heat generated by air friction at these speeds. To overcome this, Boom is leveraging advanced technologies to enhance its aircraft design. The company is using powerful CFD simulation tools to model the complex airflows that occur at supersonic speeds, allowing the engineers to optimize the design of the aircraft and ensure its performance and durability. This groundbreaking approach to airframe aerodynamics is a testament to the ingenuity and creativity of the human mind.

Boom's supersonic transport aircraft is not just a technological marvel, but also an environmental one. The aircraft has been designed to be highly fuel-efficient, with a focus on reducing carbon emissions. This is a major step forward in sustainable aviation, and it shows that we can achieve technological progress without sacrificing our commitment to the planet.

Boom is not the only party interested in supersonic commercial transportation. NASA has been heavily invested in supporting this technology through the development of its X-59 demonstration vehicle. Another challenge of supersonic commercial aviation is limiting the impact of the vehicle breaching the sound barrier on the Earth bound humans below. When that happens, air molecules cannot move out of the way of the airplane fast enough and a compressive shock wave is generated which can be experienced on the ground as a sonic boom. Right now, the FAA rules say commercial planes can't fly faster than the speed of sound because of concerns about sonic booms. The X-59 is designed to reduce sonic booms to a quiet thump. Key to quieting a sonic boom is understanding sound waves, sonic booms, and the speed of sound, as well as computational fluid dynamics simulations. You can learn all about the design of the X-59 in these slides presented by NASA engineers at NASA 2019 Super Computing conference.

As we look ahead to the next 50 years, it's clear that new players will emerge with cutting-edge technologies that will continue to drive the industry forward. Boom Supersonic is just one example of the exciting developments that are taking place in aviation today, and we can expect to see many more in the years to come.

Conclusion

The past half-century has seen significant advances in airframe aerodynamics prediction, thanks in large part to the innovative work of companies and organizations like NASA, Boeing and Boom Supersonic. While challenges remain, such as the need to develop more efficient and sustainable aircraft, the industry is on track to continue producing new designs that will enhance air travel and drive progress forward.